April 24, 2012

Key enablers for a complete family of new wear-resistant and ultra-high-strength steels were developed. Utilizing Ruukki’s own direct quenching technology the new steels bring energy efficient, light solutions for transportation as well as safety and new performance for harsh crushing and mining applications.

Key enablers for a complete family of new wear-resistant and ultra-high-strength steels were developed. Utilizing Ruukki’s own direct quenching technology the new steels bring energy efficient, light solutions for transportation as well as safety and new performance for harsh crushing and mining applications.

RESULT

Direct quenching, a new technological innovation, was developed in Ruukki. In direct quenching method hot rolled steel plate is quickly cooled from 900°C to room temperature by water. As a result of this invention, new abrasion resistant steel families were developed and the thickness range of Ruukki’s abrasion resistant steels was enlarged up to 80 mm and down to 2 mm. Optimization of process parameters and chemical compositions of these steels enables excellent combinations of mechanical properties, surface quality, thickness accuracy and especially usability in workshop and at end users. These properties extend the lifespan of machinery, increase wear resistance and save cost in different structural components and first of all decrease the ecological footprint.

The research work was implemented in cooperation with research institutes and end users. The University of Oulu investigated steel microstructure and mechanical properties and Tampere University of Technology tested the durability of the steels in the field with different kinds of laboratory equipment. Findings have been utilized into production test at Raahe Steelwork. The usability of the steels and applications in practical use was clarified mainly on the laboratory and mining equipment of Metso Oyj.

MOTIVATION

The achieved technological innovation responds the customer needs of in the area of demanding applications. The steel on a moving plant and machinery has to be though due to the demanding applications in which a steel plate gets bumped, bent and broken. This shortens steel’s lifetime and increases costs and ecological footprint. Hence, market of hard working customers demand new types of steel which are thinner, tougher and last longer.

APPLICATIONS/

IMPACT

During the project the deliveries of from 2 mm to 80 mm thick steels begun. New steel grades decreases end user’s operational and environmental costs significantly.

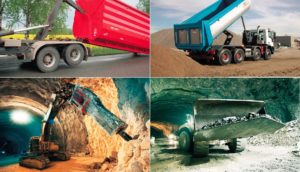

End user examples (Pictures courtesy of Ruukki)

Thicker grades serve mainly in the mining industry. These steels can be used for example to manufacture parts for heavy plant and equipment designed for excavation, loading, transporting and crushing ore in mines. Plates up to 80 mm extends the lifespan of mining construction and recycling applications. Two millimeter thin cut to length steels were developed mainly for lightweight products improving energy efficiency and lower fuel costs in transportation industry.

MAIN CONTACT

Pertti Mikkonen, Ruukki Metals Oy

PROJECT PARTNERS

Ruukki Metals Oy, Metso Oyj, University of Oulu, Tampere University of Technology